More onsite work and a trip to Scotland’s highest village!

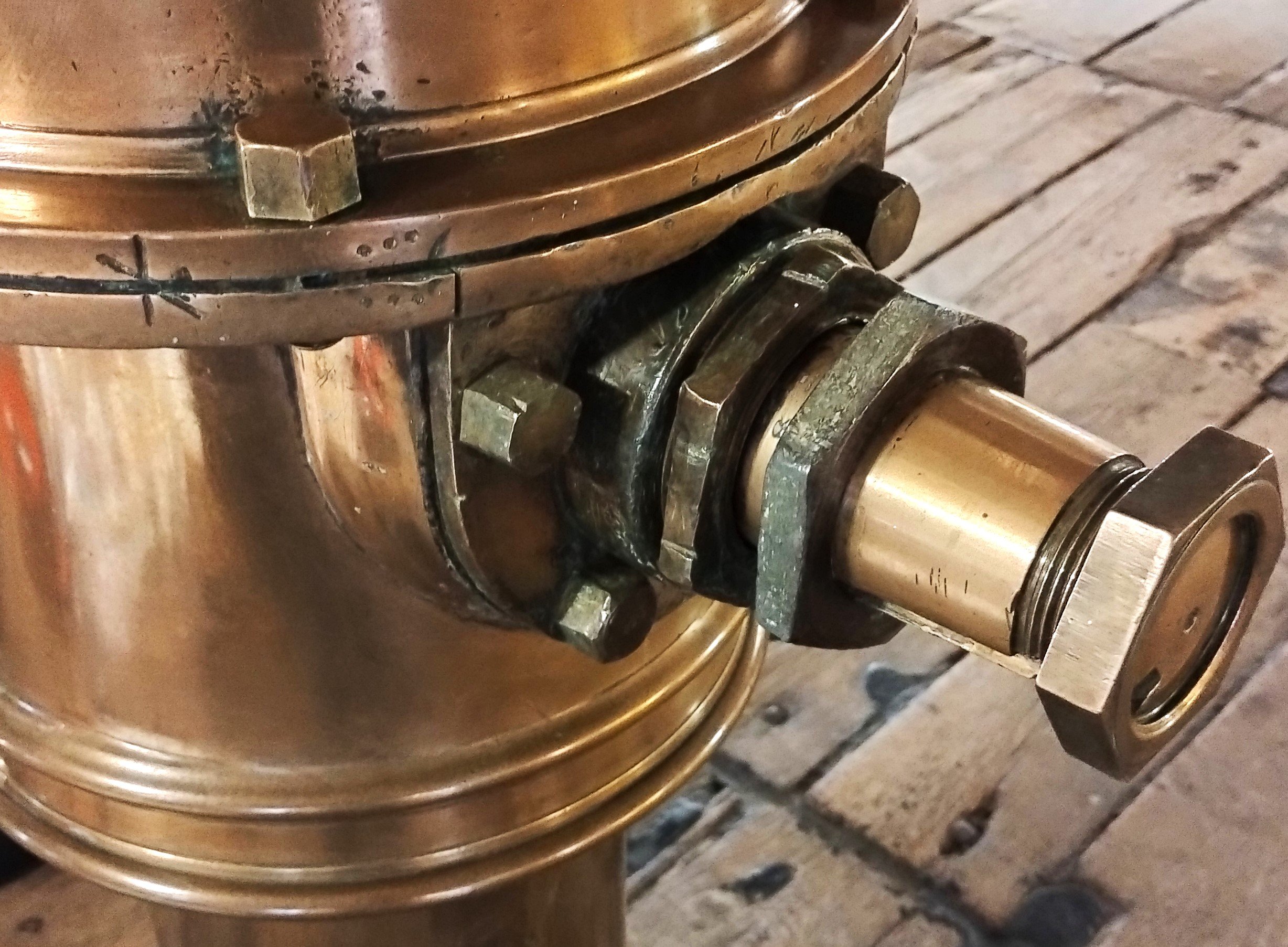

Last week, myself and fellow AOC conservator Brandon Hamer spent 4 days onsite at the HMS Unicorn, in Dundee, where we treated the Downton Pump on the ships main deck. The pump, which was patented by Jonathan Downton in 1825 and was likely fitted to the ship before it’s move to Dundee in 1873, would have been used to drain various parts of the ship. What remains of the pump on deck includes the capstan (pictured below) which would have been used to mechanically power the pump, and a valve plate, which consists of five valves that would have led to various parts of the ship.

Hard at work on the Downton Pump, HMS Unicorn

Both parts of the pump are made of brass, as well as various other cuprous and ferrous metal fittings, and both parts bore the witness marks of a life in the Navy….. they were coated with heavy amounts of Brasso residue!

Brasso was, and still is, used to polish brass metal and remove tarnish, however, it contains abrasive materials that can lead to loss of detail in the brass metal surface. It also contains ingredients that, if left, accelerate the corrosion of brass metal, resulting in the pale turquoise residues visible in the images below. The Brasso residue had also heavily stained the wooden base of the capstan.

To remove these residues, we used soft bristle brushes lightly moistened with deionized water. For more stubborn areas, we used a combination of scalpels, dental picks, and the occasional swab of fine grad wire wool to gently loosen the deposits. We wanted to be sure that we didn’t disturb the tarnish on the brass pumps, which meant it was a long a slow process; but the after treatment images show that it was all worthwhile!

Once the pump was free of Brasso residue, we coated it with microcrystalline wax to protect it against future corrosion issues.

Above: Capstan valve, before (left) & after (right) treatment

Below: Capstan base, before (left) & after (right) treatment

A trip to the Museum of Lead Mining

After work at the HMS Unicorn was completed, I took a trip out to the Museum of Lead Mining last Friday to uplift some objects, tour the site, and meet with Trustee John Evans. The Museum of Lead Mining is nestled in the Scottish Borders, in the village of Wanlockhead - the highest village in Scotland sitting 1531 feet above sea level! The visitor center sits at the site of the old blacksmith smiddy, in the center of the village, and was built in 1991 - inside you can discover how lead was mined and processed, and learn all about the geology of the area.

Mining in this area dates back to the 17th Century, with the mine finally closing in 1956, and the museum, and preserved Straitsteps cottages, also tell the story of those that lived and worked in the mines from 1750-1920.

Above: (left) Museum of Lead Mining, and (right) The Beam Engine, which was used to drain water from Straitsteps mine

During my visit, I was also treated to a tour of Lochnell mine, which was open from 1710 to 1860, and is now the only lead mine open for the public to tour in Scotland! Armed with hard hats and torches, myself and four other intrepid explorers were taken 350m underground, where our guide showed us veins of Galena (lead ore) in the rock face, and gave us a glimpse at the dangerous working conditions workers would have faced!

If you would like to find out more about either of these fascinating Go Industrial sites, follow the links below!